Capabilities

EIMCo continually invests in cutting-edge technology to provide our customers with progressive and

diverse manufacturing capabilities. EIMCo has over 50 Computerized Numeric Controlled (CNC) machines including…

CNC Machining Centers

VERTICALS

Up to 160x, 80y, and 34z work envelope, 15″ rotary fourth capable of machining complex parts such as worm gears, rotary barrel cams, etc. Rigid tapping function for tight tolerance thread depth. Three high speed machines with pallet changers.

HORIZONTALS

Up to 1000mm pallets, full fourth +-1.5 arc seconds, scales with +-.00004″ repeat.

VERTICALS

Up to 160x, 80y, and 34z work envelope, 15″ rotary fourth capable of machining complex parts such as worm gears, rotary barrel cams, etc. Rigid tapping function for tight tolerance thread depth. Three high speed machines with pallet changers.

HORIZONTALS

Up to 1000mm pallets, full fourth +-1.5 arc seconds, scales with +-.00004″ repeat.

CNC Slant Bed Lathes

Up to 29″ swing, 80″ centers, 6.5″ bar capacity. Live tooling and sub spindle equipment, up to five axis…. 3 automatic load/unload… down to 4 second total cycle. Robotic load/unload.

Up to 29″ swing, 80″ centers, 6.5″ bar capacity. Live tooling and sub spindle equipment, up to five axis…. 3 automatic load/unload… down to 4 second total cycle. Robotic load/unload.

CNC VTL

Up to 55″ Dia Swing & Turning, Live Tooling.

Up to 55″ Dia Swing & Turning, Live Tooling.

CNC Screw Machines

7 axis, 2 ¼” Bar Capacity, Twin Turrets, Twin Spindles, 12′ Hydro-dynamic Bar Feed, Swiss Style to 32MM.

CNC Controlled Lasers to 4500 Watt

Up to 6′ x 12′ sheet size 1″ thk Steel, .75 thk Stainless, .50″ thk Aluminum. Fully automated FMS system, load/unload lights out operation. Rotary Axis for tube & structural work.

Up to 6′ x 12′ sheet size 1″ thk Steel, .75 thk Stainless, .50″ thk Aluminum. Fully automated FMS system, load/unload lights out operation. Rotary Axis for tube & structural work.

Press Brakes

Up to 330 Ton 13′, 9 axis CNC controlled, Dual Crowning, Ram Repeatability .0004″

Up to 330 Ton 13′, 9 axis CNC controlled, Dual Crowning, Ram Repeatability .0004″

Grinders

CENTERLESS

Up to 4″ diameter; Surface 20 x 60

ROTARY SURFACE

Blanchard with 42″ table, 20″ height.

CNC CYLINDRICAL

12″ x 40″ with automatic gaging-tolerances to .00005.

Hobbing

8″ diameters, 20″ length of cut. 5 machines total. Broaching: Horizontal 10 ton pull to 48″ length.

CNC Plasma - Flame Cutting

12′ x 34′ table encompass, flame cutting to 6″ thick capability and plasma cutting up to 2″ thick with speeds up to 500″ per minute.

12′ x 34′ table encompass, flame cutting to 6″ thick capability and plasma cutting up to 2″ thick with speeds up to 500″ per minute.

CNC Saws

Up to 18″ Square, CNC Carbide Cold Saw up to 5.25″ Dia.

Up to 18″ Square, CNC Carbide Cold Saw up to 5.25″ Dia.

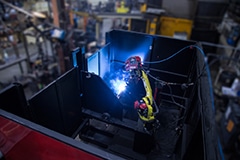

Robotic Welders & Assembly Department

Hot-wire TIG and robotic welding capabilities with up to a 10′ reach, including coordinated motion and touch-sensing.

Hot-wire TIG and robotic welding capabilities with up to a 10′ reach, including coordinated motion and touch-sensing.

Induction Heat Treat System

250 kw scanner, up to 16″ dia’s & 48″ scan lengths.

250 kw scanner, up to 16″ dia’s & 48″ scan lengths.